Description

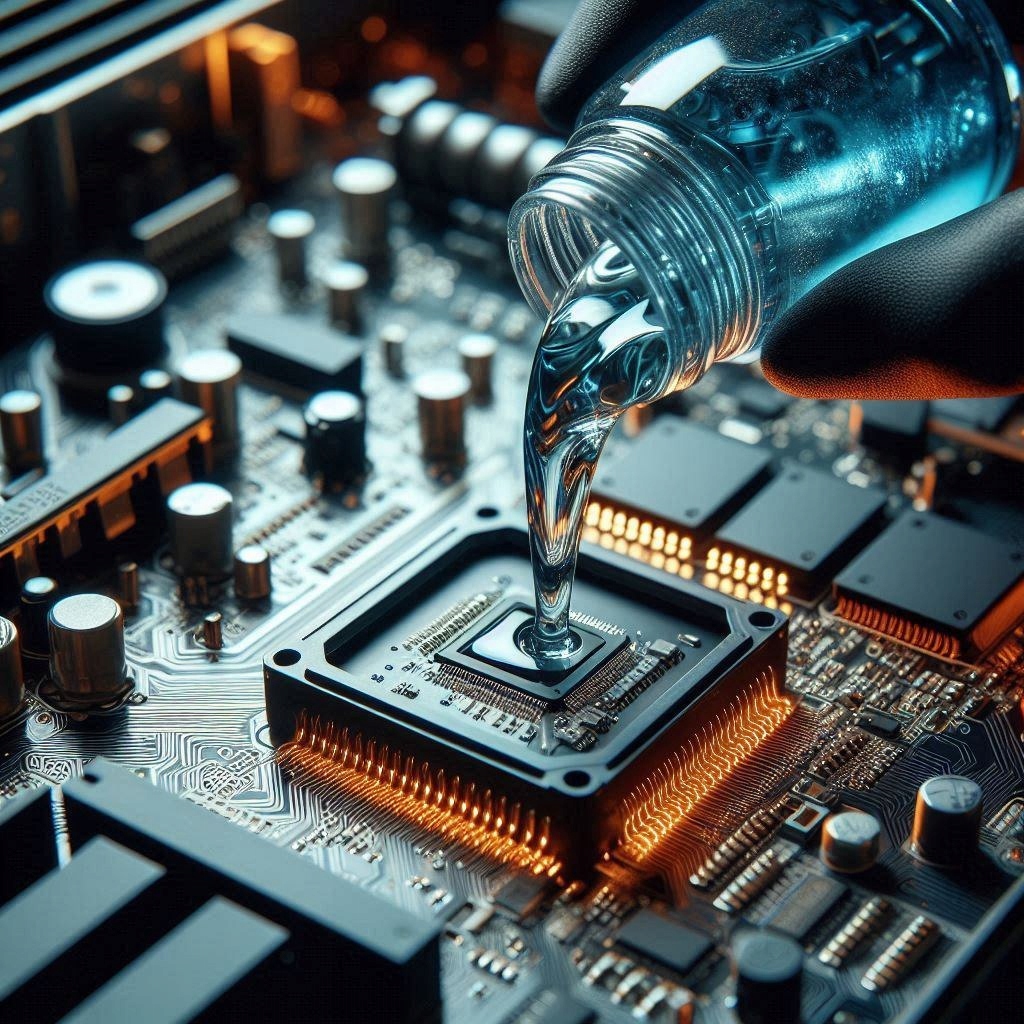

The individual components of Flexi-Eis (comp. A and comp. B) are measured out by WEIGHT in the correct ratio of 2:1.

The product is cast from bulk packaging into order-specific containers.

The absolute transparency of the composition opens up a wide range of creative possibilities: The coating can be decorated with drawings, ornaments, and any elements and materials can be inserted into the thickness of the material.

- Product in replacement packaging

Main benefits of the flexible, transparent epoxy resin: 1.

- Plasticity and resistance to cracking:

- Retains elasticity after curing to prevent cracking under mechanical stress, vibration or temperature changes.

- Ideal for applications requiring flexibility (e.g. coatings on flexible substrates, 3D models).

2 High transparency:

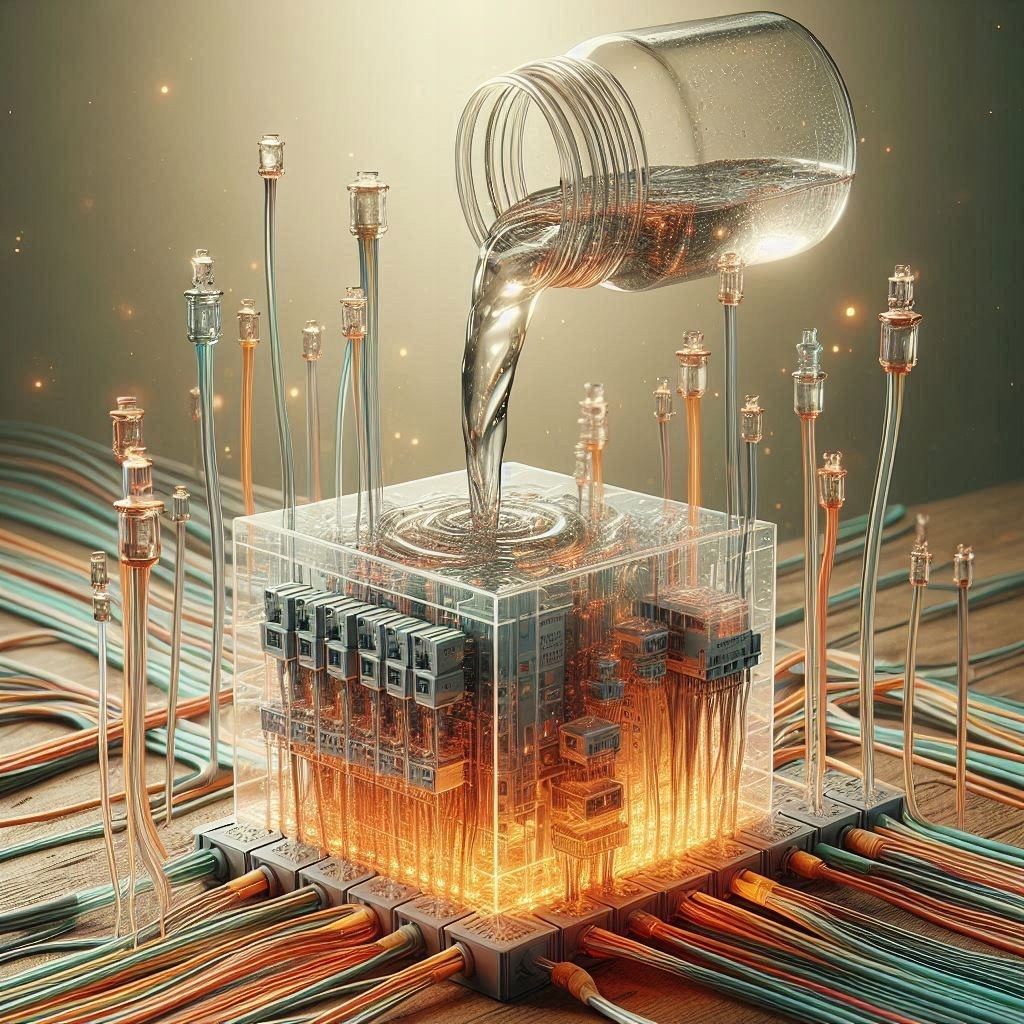

- Maintains optical clarity for decorative (e.g. art, jewellery) or technical applications (e.g. encapsulation of electronics with visible components).

3 Resistant to impact and wear:

- Thanks to its elasticity, it absorbs impact energy, which protects surfaces from damage.

- Good adhesion:

- Adheres to a variety of materials, including metal, wood, plastic and glass.

- Chemical and thermal resistance:

- Withstands solvents, oils, moisture and moderate temperatures (typically up to 80-120°C).

- Ease of application:

- Low viscosity facilitates precise application, and self-levelling creates smooth, bubble-free surfaces.

- UV Resistance (in some versions):

- Special modifications prevent yellowing when exposed to UV radiation.

Main technical features of flexible epoxy resin:.

- Extension (elongation at break):

- 20-100% (depending on formulation), providing considerable flexibility.

- Shore hardness:

- Typically in the range of Shore A 50-90 or Shore D 30-50 (lower hardness = greater flexibility).

3 Tensile strength:

- 5-15 MPa (megaPascals) – lower than in rigid resins, but sufficient for applications requiring flexibility.

4 Operating temperature:

- From 30°C to +80°C (for standard versions), special resins can withstand up to 120°C.

- Transparency:

- Light transmission rate: >90% (comparable to glass).

- Curing time:

- Gelation time: 30-60 minutes (depending on temperature and hardener).

- Full cure: 24-72 hours.

- Viscosity:

- 300-1000 mPa-s (low viscosity facilitates pouring and moulding).

- Chemical resistance:

- Withstands contact with water, oils, mild acids and bases.

- Density:

- 1.1-1.2 g/cm³ (lightness compared to metals).

Applications of flexible, transparent epoxy resin:.

- Electronics: Encapsulation of electronic circuits requiring mechanical protection and component visibility.

- Art & Design: Creating transparent, flexible coatings, figurines or decorations.

- Industry: Corrosion protection coatings on flexible surfaces (e.g. rubber), seals.

- Motorcraft: Protection of delicate components in automobiles.

Note: Properties may vary depending on manufacturer and resin chemistry. Testing on small surfaces is recommended before application.

- Product in replacement packaging.

Reviews

There are no reviews yet.